| Issue |

Int. J. Simul. Multidisci. Des. Optim.

Volume 12, 2021

Advances in Modeling and Optimization of Manufacturing Processes

|

|

|---|---|---|

| Article Number | 13 | |

| Number of page(s) | 8 | |

| DOI | https://doi.org/10.1051/smdo/2021009 | |

| Published online | 18 August 2021 | |

Research Article

Investigating the influential factors of ejective time and compressible force magnitude to fluid jet movement

Faculty of Mechanical Engineering, Ha Noi University of Industry, No 298, Cau Dien Street, Bac Tu Liem District,

Hanoi City,

Vietnam

* e-mail: nguyenvanquang@haui.edu.vn; nguyenquang.kuas@gmail.com

Received:

19

January

2021

Accepted:

12

June

2021

The molecular dynamics is the research method which is used to simulate the liquid ejection in this paper. The factors of 200000 time step (fs) total ejective time of total 200 000 time steps (fs) and various compressible forces of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 Newton (N) are main investigated in this research. These influences have action to the moveable direction of fluid jet in the whole ejective process. The research result indicates that liquid jet is prepared to separate out from nozzle plate's surface to form up droplets at the ejective time of 140 000 fs for the nozzle diameter size of 27.5 Angstrom (Å), system temperature of 310 Kelvin (K) and compressible force magnitude of 9.0 × 10−10 (N). However, when increasing the ejective time or compressible force magnitude, the jets were not only non-destruction from nozzle's surface to produce the droplets but also downward movement to go back the nozzle's surface. Meanwhile, with the nozzle diameter size of 40 Å, the droplets are not only production but also movement up to go away the nozzle under same research condition. Those prove that the ejective time and compressible force magnitude have the influences to the moveable direction of fluid jet in the whole ejective process.

Key words: Molecular dynamics simulation / influential factor / ejective time / compressible force magnitude / moveable direction of jet

© V.Q. Nguyen et al., Published by EDP Sciences, 2021

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

The molecular dynamics method is used very popular in many fields such print technology, manufacturing the electrical circuit board, etc. The requirements about the parameter choice and optimization for the devices and ejection process are always big problem which needs to solve in the development of the ejective equipment.

The study and application of nanofluidic flow in nanopores with a size of smaller than 100 nm was enabled occurrence with the great potential in the related energy fields [1]. The breakup of a liquid jet for a diameter of few nanometers based on a stochastic differential equation derived recently was studied by Moseler and Landman. The study also shows that the capable of capturing the dynamics of nano-scale liquid jets using the Langevin dynamics simulations is investigated about behave in close agreement with the theoretical prediction for nano-size jet [2–5].

The molecular dynamics method was adopted for establishing the fluidic nanojet and droplet formation process. A combination of the Lennard-Jones and Coulomb potentials for interacting between the water charge distributions with the metal molecules is employed for the water and device's wall interactions [6–12].

The influence of temperature and aperture size parameters on the liquid ejection process was performed by using molecular dynamics simulation method. According to the analysis, the nanojet aperture is distributed as the temperature is increased under these effects. The droplet formation and ejection behavior of droplets were also investigated for two types of water and ethylene glycol fluids. Otherwise, the effect of positive voltage keeping time operating frequency, and pulse voltage magnitude on the fluid droplet magnitude and velocity was discussed [13–17].

The experimental researches about droplet collision dynamics on the solid plate's surface under effect of various temperature values were investigated. The evolution of the liquid film width was measured as a function of surface temperature for each different impaction [18–19].

Many scientists had studied about the liquid ejection topic by the simulative and experiment method. The effect of the technology parameters to the ejective process was investigated in the previous papers. However, the influential factors of the ejective time and compressible force magnitude to the jet moveable direction of fluid jet in the whole ejective process have little been researched. This investigation is a continuation of a former study for surveying the factors of the ejective time and compressible force magnitude how does they effect to the fluid jet movement in the fluidic ejective process [20].

2 Research method

2.1 Research model

The molecular model is created for the simulative performance which shows as in Figure 1. The device wall is made by gold atom (Au) with the five layers of the total thickness of 8.152 Å which is arranged into face-centered cubic crystal lattice structure. A circular nozzle hole is designed at the center of device's lid. The device's bottom plate can slid in the vertical direction along to the device's wall. The liquid molecules are a water block with dimensions of the height of 42.248 Å and widths of 101.9 Å which are contained inside the ejective device. The periodic boundary condition is set up for bounding along the vertical direction of the water block.

|

Fig. 1 Molecular model. |

2.2 Atomic and molecular interaction

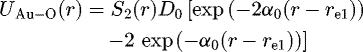

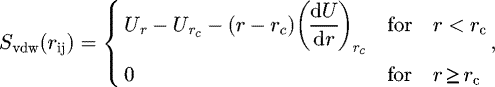

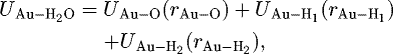

The specific potential model is adopted in this research to show the interaction between the gold atoms together. The equation (1) is the energy function of the F3C molecule model while the value of energy function is the sum of the bonding, bending, van der Waals and Coulomb terms [21]. (1)with Svdw(rij) is a truncation shift function of the van der Waals force as shown in the equation (2):

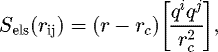

(1)with Svdw(rij) is a truncation shift function of the van der Waals force as shown in the equation (2): (2)and Sels(rij) is the shift function of the Coulomb's force and as shown in the equation (3):

(2)and Sels(rij) is the shift function of the Coulomb's force and as shown in the equation (3): (3)

(3)

Meanwhile  are respectively force coefficient of the short distance, harmonic force constant, constant of angle bending force, bond length of ith O-H, equilibrium length of O-H bond, bond angle of ith H-O-H, equilibrium angle of H-O-H bond, interatomic distance, and cutoff distance. With qi and qj are O or H partial charge.

are respectively force coefficient of the short distance, harmonic force constant, constant of angle bending force, bond length of ith O-H, equilibrium length of O-H bond, bond angle of ith H-O-H, equilibrium angle of H-O-H bond, interatomic distance, and cutoff distance. With qi and qj are O or H partial charge.

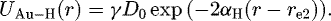

Spohr potential function presents the interaction among the Au atoms and H2O molecules as shown in the equation (4): (4)

(4)

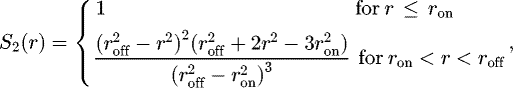

with the switch function of S2(r) is shown as in the equation (7): (7)

(7)

while ron and roff are the starting and ending distances in the switch function which have the magnitudes of 7.0 and 11.0 Å, respectively.

2.3 Parameter table

The research cases include 6 sets of two nozzle diameter sizes of 27.5 and 40 Å, one value of system temperature of 310 K and three compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N as shown in Table 1.

Parameter table.

3 Results and discussion

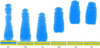

The fluid molecules were ejected through the nozzle diameter sizes of 27.5 and 40 Å under the various compressible force magnitudes of 9.0 × 10−10, 10.0 ×10−10 and 11.0 × 10−10 N and the same a system temperature value of 310 K at total ejective time of 75 000 fs which are shown as in Figure 2. Meanwhile, Figures 2a–2c are respectively the jets of 27.5-Å-nozzle diameter for various force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N. The Figures 2d–2f are the jets of 40-Å-nozzle diameter for various force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N, respectively.

In the same input condition, the fluid molecules have not completed to eject all out through the nozzle mouth at 75 000 fs for the cases as shown in the Figures 2a and 2b. Besides, the almost molecules have completed for ejecting through the nozzle mouth to build up the jet on the nozzle's surface for the case as shown in the Figure 2c with the nozzle diameter of 27.5 Å. The split phenomenon of jet from the nozzle plate is the most clearest in this case.

Contrarily, the all molecules were easy to eject through the nozzle mouth to produce the fluid droplets at 75000 fs for all the cases of the nozzle diameter of 40 Å as shown in Figures 2d–2f.

The Figure 3 shows the fluid jets for the nozzle diameter sizes of 27.5 and 40 Å at 90 000 fs the compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 ×10−10 N and the same system temperature value of 310 K.

For the nozzle diameter of 27.5 Å, the fluid molecules also have not finished to eject all fluid out of the ejective device at 90 000 fs with the case as showing in the Figure 3a. While, the almost molecules were ejected out through the nozzle mouth to establish the jets for the case as shown in the Figures 3b and 3c. The jet has the clearest split ability to produce the droplets at 90000 fs as shown in the photo of Figure 3b. The photo shows that the jet has the movement down in a comparison with the photo of Figures 2c when increasing the ejective time from 75000 fs to 90000 fs.

For the nozzle diameter of 40 Å, after establishing the fluid jets at 75000 fs, they continue to move up away the nozzle when increasing the ejective time to 90000 fs as shown in Figures 3d–3f.

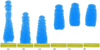

The almost fluid molecules were ejected out of the device at the total ejective time of 140 000 fs for the nozzle diameters of 27.5 and 40 Å, the compressible forces of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N and the system temperature of 310 K as shown as in Figure 4.

The Figure 4a presents that the jet dissociative phenomenon of jet from nozzle's surface to separate the droplets is the most obvious at the time of 140 000 fs. The Figures 4b and 4c show the reducing jet height of jets that the jets have the movement down in the comparison with the photo of Figures 3b and 3c when increasing the ejective time from 90 000 to 140 000 fs.

The Figures 4d–4f are a continuous movement up away the nozzle plate's surface for the diameter of 40 Å in the comparison with the photo of Figures 3d–3f when increasing the time from 90 000 to 140 000 fs.

In the comparison among the photos of Figure 5 with the photos of Figure 2, the result give out two contrary movements of fluid jets between two nozzle diameter sizes of 27.5 and 40 Å when increasing the ejective time to 200000 fs.

With the nozzle diameter of 27.5 Å, the fluid jets are not only non-destruction from nozzle plate's surface to produce the droplets but also downward movement to come back the nozzle's surface when increasing the ejective time to 200 000 fs. The clearances of destroyable phenomenon between the jets and nozzle plate's surface were filled up by the downward movement molecules of jet. The jet's height was reduced in these cases as shown as in Figures 5a–5c.

Contrarily, with the nozzle diameter of 40 Å, the droplets were separated out which were continuous movement up to leave away the nozzle plate's surface under same above conditions. The distance form jets to the nozzle plate increases for these cases as shown as in Figures 5d–5f.

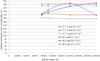

The plot presents the distance change from the jet's top to the nozzle's surface as showing in Figure 6. These distance increases gradually in the whole ejective time from 0 to 74 000 fs for all the cases of nozzle diameters of 27.5 and 40-Å under the compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N. Specially, the distance reaches to the biggest and earliest value at the ejective time of 74 000 fs for the case of nozzle diameter of 27.5 Å under the compressible force of 11.0 × 10−10 N. After this time, each magnitude of nozzle diameter and compressible force has the different influences to the fluid jet's movement direction. Meanwhile, after getting the highest position, jet has the downward movement to go back very slowly to the nozzle plate in the remained time of simulative process for the case of nozzle diameter of 27.5 Å under the compressible force magnitude of 11.0 × 10−10 N.

Concretely, the jet continues to move up for the nozzle diameter of 27.5 Å with the compressible forces of 9.0 × 10−10, 10.0 × 10−10 N. The jet's top reaches to the highest position at the ejective time of 90 000 and 140 000 fs for the nozzle diameter of 27.5 Å under the compressible forces of 10.0 × 10−10 and 9.0 × 10−10 N, respectively. After that, this jet also has the downward movement to go back to the nozzle plate in the continuing time of ejective process.

For the nozzle diameter of 40 Å, the jet has the movement up in the whole ejective process from 0 to 200 000 fs with the compressible force magnitude of 9.0 × 10−10 N. While, the jet virtually does not have the change about the distance from the jet's top to the nozzle's surface after getting the highest position under the compressible force of 9.0 × 10−10 N in the ejective process.

From the analysis result and the plots of Figure 6 give that the different compressible forces and ejective time have the important influence to the jet's movement in the ejective process.

Plots of molecular weight density inside the device are presented as in the Figure 7 for two sizes of nozzle diameter of 27.5 and 40 Å at each 5000 fs. At the status before ejecting the fluid molecules through the nozzle, the stable value of the molecular weight density for all research cases is about 0.378 g/cm3. However, this value increases very rapidly to average weight density of 0.78 g/cm3 for the nozzle diameter of 27.5 Å and compressible forces of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N. After that the densities transform in a narrow band and maintain for a quite long ejective time of 50 000 fs. The weight density magnitude is longer maintainable for smaller compressible force value with same size of nozzle diameter. These molecular weight densities rapidly reduce to the near initial value of 0.378 g/cm3 for all compressible force cases of the nozzle diameter of 27.5 Å. Contrarily, the nozzle diameter of 40 Å, the weight densities have a very small value of whole ejective process in comparison with the size of nozzle diameter of 27.5 Å. The long maintainable time of the molecular weight density inside the device explains that the molecules have a longer existence, movement and collision time inside the device for the size of smaller nozzle diameter. Therefore, the molecular energy and velocity is declined very much before ejecting out through the nozzle for the smaller nozzle diameter and compressible force magnitude. This proves that the ejective time and compressible force magnitude have the influences to the jet's movement direction.

Table 2 is the synthetic result about the influential factor of ejective time to the fluid jet movement for two nozzle diameter sizes of 27.5 and 40 Å under same system temperature and compressible force.

For the nozzle diameter of 27.5 Å, the jets were established on the nozzle's surface which finally have the movement down in increasing the ejective time of the simulative process under the same temperature value of 310 K and different compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N.

Meanwhile, the fluid jets were established which have movement up to leave away the nozzle in the all ejective time for the nozzle diameter of 40 Å and the same above conditions of the temperature value and compressible force magnitude as showing in the Table 2.

The research result indicates that liquid jet prepares to separate out from nozzle's surface to form up droplets for the all cases of nozzle diameter of 27.5 Å. However, when increasing the ejective time, the jets are not only non-destruction to produce the droplets but also downward movement to go back the nozzle's surface. Meanwhile, for the all cases of the nozzle diameter of 40 Å, the droplets are not only production out but also movement up to leave away the nozzle's surface under same condition as the nozzle diameter of 27.5 Å. Those prove that the ejective time has the influence to the moveable direction of fluid jet in the whole ejective process.

|

Fig. 2 Liquid jets at 75 000 fs. (a–c) are jets of 27.5-Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N; (d–f) are jets of 40 Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N. |

|

Fig. 3 Liquid jets at 90 000 fs. (a–c) are jets of 27.5-Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N; (d–f) are jets of 40 Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N. |

|

Fig. 4 Liquid jets at 140 000 fs. (a–c) are jets of 27.5-Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N; (d–f) are jets of 40 Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N. |

|

Fig. 5 Liquid jets at 200 000 fs. (a–c) are jets of 27.5-Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N; (d–f) are jets of 40 Å-nozzle diameter for various compressible forces of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N. |

|

Fig. 6 Molecular densities inside the ejective device. |

|

Fig. 7 Molecular weight density inside the ejective device. |

Influential factor of ejective time to fluid jet movement.

4 Conclusions

The factors of compressible force and ejective time were used to study about their influences to the movement direction of fluid jet at the each stages of ejective process. The obtained results are summarized the following:

The fluid jets have built up on the nozzle's surface under the same temperature value of 310 K and different compressible force magnitudes of 9.0 × 10−10, 10.0 ×10−10 and 11.0 × 10−10 N for the nozzle diameters of 27.5 and 40 Å.

For the nozzle diameter of 27.5 Å and compressible force magnitudes, the split phenomenon of jet from the nozzle plate is quite clear at the different ejective times. But, the jets have finally not broken out to produce the droplets. Contrarily, the jets have the downward movement back to the nozzle after getting the biggest distance from the jet's top to the nozzle's surface. The downward movement speed jet depends on the magnitudes of compressible force.

Meanwhile, the droplets after breaking from the jet continue to move away the nozzle plate for the nozzle diameter of 40 Å under the temperature value of 310 K and compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N. The different ejective times and compressible force magnitudes have different decisions to the upward movement of droplets and the distance from the jet's top to the nozzle plate's surface.

The evidences are also supplied to prove and explain for the influences of factors as ejective time and compressible force magnitude to the fluid jet's movement.

Acknowledgments

This research is supported by Department of Sciences and Technology, Hanoi University of Industry, Viet Nam.

References

- C. Duan, W. Wang, Q. Xie, Fabrication of nanofluidic devices, Biomicrofluidics 7, 1932–1058 (2013) [CrossRef] [Google Scholar]

- A. Dalili, S. Chandra, J. Mostaghimi, Formation of liquid sheets by deposition of droplets on a surface, J. Colloid Interface Sci. 418, 292–299 (2014) [CrossRef] [Google Scholar]

- Y. Li, J.X. Dong, D. Li, Molecular dynamics simulation of nanoscale liquid flows, Microfluid. Nanofluid. 9, 1011–1031 (2010) [CrossRef] [Google Scholar]

- J. Eggers, Dynamics of liquid nanojets, Phys. Rev. Lett. 89, 1–4 (2002) [CrossRef] [PubMed] [Google Scholar]

- N. Gopan, S.P. Sathian, A Langevin dynamics study of nanojets, J. Mol. Liquids 200, 246–258 (2014) [CrossRef] [Google Scholar]

- J.W. Lin, S.X. Chu, Molecular dynamics simulations of nanoscale water jet, in: Proceedings of MNHT2008 Micro/Nanoscale Heat Transfer International Conference , Taiwan, January 2008, pp. 6–9 [Google Scholar]

- N. Gopan, S.P. Sathian, The role of thermal fluctuations on the formation and stability of nano-scale drops, Colloids Surf. A Physicochem Eng. Asp. 432, 19–28 (2013) [CrossRef] [Google Scholar]

- N. Gopan, S.P. Sathian, A langevin dynamics study of nanojets, J. Mol. Liq. 200, 246–258 (2014) [CrossRef] [Google Scholar]

- M. Jia, B.Y. Jae, Z. Xuehua, Viscosity-mediated growth and coalescence of surface nanodroplets, J. Phys. Chem. C 124, 12476–12484 (2020) [CrossRef] [Google Scholar]

- J. Zhao, Study on the cylindrical liquid nanojet break-up phenomenon, J. Thermal Sci. 24, 194–201 (2015) [CrossRef] [Google Scholar]

- A. Suphanat, Y.M.A. Elisa, Y. Jingjie, Y.N. Teng, Many-body dissipative particle dynamics simulations of nanodroplet formation in 3D nano-inkjet printing, Modell. Simulation Mater. Sci. Eng. 27 (2019) [Google Scholar]

- Q. Jiasheng, F.A. Gilmar, Z. Xuehua, Surface nanodroplets: formation, dissolution, and applications, Langmuir 35, 12583–12596 (2019) [CrossRef] [Google Scholar]

- T.H. Fang, W.J. Chang, S.C. Liao, Effects of temperature and aperture size on nanojet ejection process by molecular dynamics simulation, Microelectron. J. 35, 687–691 (2004) [CrossRef] [Google Scholar]

- J. Huicong, T. Hua, One dimensional model for droplet ejection process in inkjet devices, MDPI and ACS Style, 28 (2018) [Google Scholar]

- Q. Li, Q. Liu, Molecular dynamics simulation of heat transfer with effects of fluid–lattice interactions, Int. J. Heat Mass Transfer 55, 8088–8092 (2012) [CrossRef] [Google Scholar]

- H.J. Lin, H.C. Wu, T.R. Shan, W.S. Hwang, The effects of operating parameters on micro-droplet formation in a piezoelectric inkjet printhead using a double pulse voltage pattern, Mater. Trans. 47, 375–382 (2006) [CrossRef] [Google Scholar]

- Q.N. Van, S.P. Xuan, W.L. Jau, Separation criteria of nanoscale water droplets from a nozzle plate surface, in: MATEC Web of Conferences , 2018, 169, 01016 [CrossRef] [EDP Sciences] [Google Scholar]

- S.L. Manzello, J.C. Yang, An experimental investigation of water droplet impingement on a heated wax surface, Int. J. Heat Mass Transfer 47, 1701–1709 (2004) [CrossRef] [Google Scholar]

- J.W. Lin, Studying on water nanojet ejection and the wetting phenomena on the nozzle surface, Microfluid. Nanofluid. 13, 37–48 (2012) [CrossRef] [Google Scholar]

- Q.N. Van, W.L. Jau, Investigation of temperature effects on nanoscale water droplet separation onto a fixed solid plate, Simulation: Trans. Soc. Model. Simulation Int. 1–9 (2016) [Google Scholar]

- M. Levitt, M. Hirshberg, R. Sharon, K.E. Laidig, V. Daggett, Calibration and testing of a water model for simulation of the molecular dynamics of proteins and nucleic acids in solution, J. Phys. Chem. B 101, 5051–5061 (1997) [CrossRef] [Google Scholar]

Cite this article as: Van Quang Nguyen, Van Thien Nguyen, Tien Dung Hoang, Investigating the influential factors of ejective time and compressible force magnitude to fluid jet movement, Int. J. Simul. Multidisci. Des. Optim. 12, 13 (2021)

All Tables

All Figures

|

Fig. 1 Molecular model. |

| In the text | |

|

Fig. 2 Liquid jets at 75 000 fs. (a–c) are jets of 27.5-Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N; (d–f) are jets of 40 Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N. |

| In the text | |

|

Fig. 3 Liquid jets at 90 000 fs. (a–c) are jets of 27.5-Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N; (d–f) are jets of 40 Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N. |

| In the text | |

|

Fig. 4 Liquid jets at 140 000 fs. (a–c) are jets of 27.5-Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N; (d–f) are jets of 40 Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N. |

| In the text | |

|

Fig. 5 Liquid jets at 200 000 fs. (a–c) are jets of 27.5-Å-nozzle diameter for various compressible force magnitudes of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N; (d–f) are jets of 40 Å-nozzle diameter for various compressible forces of 9.0 × 10−10, 10.0 × 10−10 and 11.0 × 10−10 N. |

| In the text | |

|

Fig. 6 Molecular densities inside the ejective device. |

| In the text | |

|

Fig. 7 Molecular weight density inside the ejective device. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.